Several options for unloading: on one or three sides.

The sides can be made of metal or aluminum profiles.

Unloading control using a remote control.

Bakelite plywood or metal sheets are used as flooring.

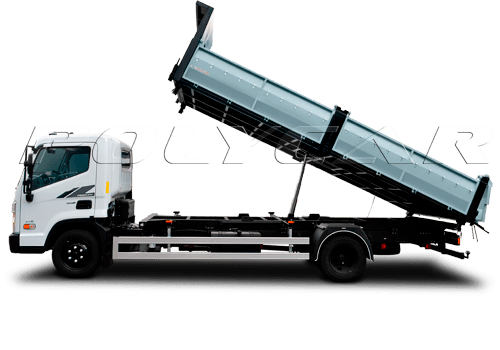

Grain tippers are vehicles designed for the transportation of various goods, which, perform quick unloading using hydraulic equipment.

There are several options for unloading a grain tipper: on one and on three sides, the first is rarely used, usually these are high-capacity versions that work in places where there is no limited space for unloading. If there is a choice, due to the small difference in price, most customers choose the three-way unloading option. Unloading is controlled by a remote control. The sides can be made of metal or aluminum profiles and have mechanisms that allow them to be opened in the lower and upper parts, it is also possible to completely remove the side. Bakelite plywood or metal sheets are used as floor coverings. In most cases, this body is equipped with an awning, in the front there is an awning twisting system. There are several versions for various tasks and body types.

We have completed a huge number of grain tippers based on various brands of truck chassis (Isuzu, Ford, Renault, Iveco, Daewoo, MAZ, KAMAZ, GAZ, and this is not a complete list of the company’s ready-made solutions), projects that include a crane-manipulator are also in great demand, it is installed behind the cab and is capable of loading / unloading various cargoes weighing up to several tons. A required condition for the production of such platforms is a high front wall, which protects the cabin from mechanical damage during loading and unloading. We provide several options for the execution of this protection to choose from, depending on the customer’s wishes and tasks. We specialize in the production of grain tippers of various types, from small to construction grain tippers with high load capacity and strength.

You can get more detailed information about grain tippers, their design, prices and terms of production for your vehicle by contacting the managers of our company. They will orient you on the main issues that you should pay attention to and help with the selection of components, chassis and additional equipment.

Технічні характеристики

| Side material | metal or aluminum |

| Sides | the front side is rigidly attached to the platform, the rest are folding |

| The height of the sides is | from 600 mm |

| Flooring | bakelite plywood / metal |

| Platform | welded construction made of steel profiles with 4 support balls |

| Control | remote control |

| Moving mechanism | hydraulic cylinder with a platform |

| Unloading options | on one or three sides |

| Hydraulic cylinder | model depends on the load capacity |

| Additionally | tent with fastening, side protection, wheel arch liners, clearance and marker lights |

Відеофайли